|

The charging of the line can be

effected by hand or automatically. The substrates are laid on the transport

belt. As transport means paper or foil can be used. The substrate is

transported from the entry through the spraying booth to the exit.

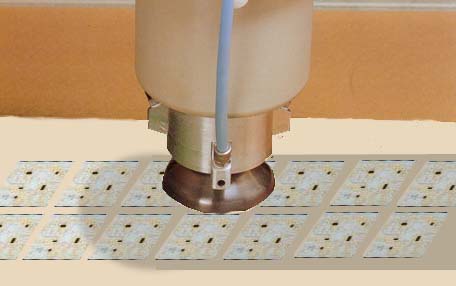

Within the spraying booth the

substrates are coated with ink which is atomized by a rapidly rotary bell and

charged with high voltage.

The distance between the

atomizing bell and the substrate can be continously adjusted by motor.

A continiously adjustable gear

pump supplies the high speed rotary bell directly from the ink drum. In case

that several ink have to be held available, each of them is provided with a

pump and a branch hose to the atomizer. In this way changes from one ink to

another can be effected in a few seconds by a short flush of the bell.

Also conductive ink can be

sprayed because of the special design. Near the exit after having left the

spray booth the boards are transported through a flash-off zone where highly

volatile solvents evaporate.

Air is cleaned with finest filter

before entering the spray booth.

The spray cabine is under light

pressure to prevent outer influences like dust etc. from entering. Possibly

escaping solvent

emissions are sucked off in the

entry and exit zones to prevent spoiling solvent emissions from entering the

cabine and disturbing the operation staff's work.

The air from the inside of the booth is sucked out

via filtering mats fixed on both sides of the transport belt within the

booth. |