|

|

Advantages

Advantages

|

|

The CORESOL

technology enables:

- The automation of your PCB-production

- An extremely flexible level of compatibility featuring quick adjustmant of the

unit to suit varying workpieces ans systems of lacquering. The systenm also accomodates irregular and sructured workpieces.

- A

marked improvement in the coating quality, due to the fact, that the method is

contact-free and operates without circulating flow of laquer.

|

|

|

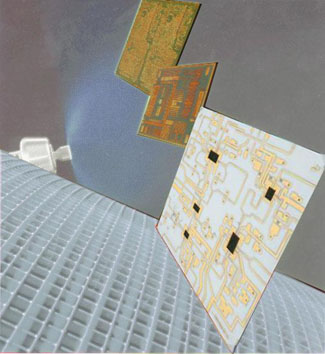

An outstanding applicating system for photosensitive materials in the production of

thin film on substrates like wafers, LCD´s and hybrid integrated circuits.

The name

CORESOL stands for a coating technology, which utilizes a method, whose

advantages have already been gained for a long time in other fields of surface

coating: the technology of electrostatic spray coating.

With this technology

resists and solder masks can be sprayed on flat substrates like circuit boards,

inner layers, hybrids, wafers and LCDs. |

From now on printed circuit board coating is

more economical, and more precise.

The CORESOL

system sets new standards of quality in the electrostatic liquid resists

coating of circuit boards.

The process

meets the requirements of complex circuits and the SMD Technology.

The CORESOL

concept also includes future solutions for structures with minimal pitches.

It is the result of intensive research

together with the resist-manufacturers and users.

|